Autogenerative high-pressure digestion

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

Autogenerative high-pressure fermentation (AHPD) is a biogas production technique that operates under elevated gas pressure. This pressure is naturally generated by the bacteria and archaea through the gases they release. First described by R. Lindeboom of University of Wageningen (WUR) in 2011[1], a batch reactor was pressurized to 58 bar, yielding a methane concentration of 96% in the resulting biogas. This method is also commonly referred to in scientific literature as High Pressure Anaerobic Digestion (HPAD).

AHPD leverages the higher solubility of carbon dioxide (CO2) at 0.031 mol/L/bar compared to methane (CH4) at 0.0016 mol/L/bar. This difference allows more CO2 to dissolve in the digestate, while hydrogen sulfide (H2S) also dissolves more efficiently under pressure. The result is biogas with a higher methane content, which requires less upgrading to meet natural gas standards, ultimately reducing processing costs.[2][failed verification]

Microbial composition

[edit]Individual species of microorganism have different optimal conditions in which they grow and replicate most rapidly [citation needed] and a [| range] around that optimum in which the species is able to survive. [3] Commonly known are pH, temperature, [4] osmotic pressure (often caused by salinity), etc. Lesser known is pressure as a factor that influence microbial growth. Some species are able to survive in extremophile conditions such as extreme radiation, temperature, salinity or pressure. Piezophile microorganisms have their optimal growth condition at a pressure equal to or above 10 megapascals (99 atm; 1,500 psi).[citation needed] Some bacteria and archaea have adapted to life in the deep oceans, where the pressure (Hydrostatic pressure) is much higher than at sea level. For example, the methane-producing archaea species Methanocaldococcus, Methanothermococcus, Methanopyrus and Methanotorris have been found in hydrothermal vents in the ocean floor.[5] Research at the University of Groningen (RUG) has shown that the bacterial community is affected by pressure from composition changes.[6] This makes it possible to influence the anaerobic digestion process.

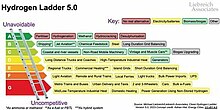

A further development of this technique is the addition of hydrogen gas to the reactor. According to Henry's law this gas also dissolves more at increased pressure.[citation needed] The result is that it can be better absorbed by bacteria and archea. These then convert the hydrogen gas with the already dissolved carbon dioxide into additional methane. This combination of techniques was described in detail by Kim et all in 2021.[7] This process is known as biological methanation. On Michael Liebreich's hydrogen ladder 5.0, this form of biogas upgrading is at step C. [8] [citation needed] This is considerably higher than applications as fuel in vehicles. These are spread over steps D to G.[9]

Although the technique is usually used as a fermentation process for thick liquid flows and solid biomass, it can also be applied as anaerobic Wastewater treatment. In South Korea they have succeeded in operating a UASB reactor (a form of anaerobic wastewater treatment) at 8 Bar. [10] A biogas was then created with a methane content of 96.7%. A remarkable finding was that the grains in the sludge that are so characteristic of the UASB technique were well preserved. This was because more Extracellular polymeric substance (EPS) was formed in the biofilm. Microorganisms make these to protect themselves against difficult conditions. In this case the pressure.[spelling?]

See also

[edit]References

[edit]- ^ R.E.F. Lindeboom (2011). "Autogenerative high pressure digestion: Anaerobic digestion and biogas upgrading in a single step reactor system". Water Science & Technology. 64 (3): 647–653. doi:10.2166/wst.2011.664. PMID 22097043.

- ^ Liang, Z., Wilkinson, D.W., Wang, C. (2023). "Pressurised Anaerobic Digestion for Reducing the Costs of Biogas Upgrading". Bioenerg. Res. 16 (4): 2539–2548. Bibcode:2023BioER..16.2539L. doi:10.1007/s12155-023-10602-w.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Libretexts Biology 17.2: Factors that Influence Bacterial Growth https://bio.libretexts.org/Bookshelves/Microbiology/Microbiology_(Kaiser)/Unit_7%3A_Microbial_Genetics_and_Microbial_Metabolism/17%3A_Bacterial_Growth_and_Energy_Production/17.2%3A_Factors_that_Influence_Bacterial_Growth

- ^ Libretexts Biology 8.3: The Effects of pH and Temperature on Microbial Growth https://bio.libretexts.org/Courses/Manchester_Community_College_(MCC)/Remix_of_Openstax%3AMicrobiology_by_Parker_Schneegurt_et_al/08%3A_Microbial_Growth/8.03%3A_The_Effects_of_pH_on_Microbial_Growth

- ^ Zeng, X., Alain, K. & Shao, Z. (2021). "Microorganisms from deep-sea hydrothermal vents" (PDF). Marine Life Science & Technology. 3 (2): 204–230. Bibcode:2021MLST....3..204Z. doi:10.1007/s42995-020-00086-4. PMC 10077256. PMID 37073341.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Zhao J, Li Y, Zhang Z (February 2023). "Hydraulic retention time and pressure affect anaerobic digestion process treating synthetic glucose wastewater" (PDF). Bioresource Technology. 370 128531. Bibcode:2023BiTec.37028531Z. doi:10.1016/j.biortech.2022.128531. PMID 36574891.

- ^ Sangmi Kim (2021). "Production of high-calorific biogas from food waste by integrating two approaches: Autogenerative high-pressure and hydrogen injection". Water Research. 194. Bibcode:2021WatRe.19416920K. doi:10.1016/j.watres.2021.116920. PMID 33609909.

- ^ The Hydrogen Ladder https://www.smoltek.com/investors/blog/the-hydrogen-ladder/6778/

- ^ "Hydrogen Ladder | Seven H2 applications relegated in updated use-case analysis, but three promoted". 23 October 2023.

- ^ Om Prakash (2023). "Upflow anaerobic sludge blanket reactor operation under high pressure for energy-rich biogas production". Bioresource Technology. 376. Bibcode:2023BiTec.37628897P. doi:10.1016/j.biortech.2023.128897. PMID 36931446.

This article needs additional or more specific categories. (August 2024) |