User:07JOS/Pyrolysis

| This is the sandbox page where you will draft your initial Wikipedia contribution.

If you're starting a new article, you can develop it here until it's ready to go live. If you're working on improvements to an existing article, copy only one section at a time of the article to this sandbox to work on, and be sure to use an edit summary linking to the article you copied from. Do not copy over the entire article. You can find additional instructions here. Remember to save your work regularly using the "Publish page" button. (It just means 'save'; it will still be in the sandbox.) You can add bold formatting to your additions to differentiate them from existing content. |

Article Draft

[edit]Lead

[edit]Article body

[edit]Pyrolysis has also been used for trying to mitigate tobacco waste. A group of researchers separated tobacco waste into two categories TLW (Tobacco Leaf Waste) and TSW (Tobacco Stick Waste). TLW was determined to be any waste from cigarettes and TSW was determined to be any waste from electronic cigarettes. Both TLW and TSW were dried at 80 °C for 24 hours and stored in a desiccator[1]. Samples were grounded so that the contents were uniform. Tobacco Waste (TW) also contains inorganic (metal) contents, which was determined using an inductively coupled plasma-optical spectrometer[1]. Thermo-gravimetric analysis was used to thermally degrade four samples (TLW, TSW, glycerol, and guar gum) and monitored under specific dynamic temperature conditions[1]. About one gram of both TLW and TSW were used in the pyrolysis tests. During these analysis tests, CO2 and N2 were used as atmospheres inside of a tubular reactor that was built using quartz tubing. For both CO2 and N2 atmospheres the flow rate was 100 mL min-1[1]. External heating was created via a tubular furnace. The pyrogenic products were classified into three phases. The first phase was biochar, a solid residue produced by the reactor at 650 °C. The second phase liquid hydrocarbons were collected by a cold solvent trap and sorted by using chromatography. The third and final phase was analyzed using an online micro GC unit and those pyrolysates were gases.

Two different types of experiments were conducted: one-stepwise pyrolysis and two-stepwise pyrolysis. One-stepwise pyrolysis consisted of a constant heating rate (10 °C min-1) from 30 to 720 °C[1]. In the second step of the two-stepwise pyrolysis test the pyrolysates from the one-stepwise pyrolysis were pyrolyzed in the second heating zone which was controlled isothermally at 650 °C[1]. The two-stepwise pyrolysis was used to focus primarily on how well CO2 affects carbon redistribution when adding heat through the second heating zone[1].

First noted was the thermolytic behaviors of TLW and TSW in both the CO2 and N2 environments. For both TLW and TSW the thermolytic behaviors were identical at less than or equal to 660 °C in the CO2 and N2 environments. The differences between the environments start to occur when temperatures increase above 660 °C and the residual mass percentages significantly decrease in the CO2 environment compared to that in the N2 environment[1]. This observation is likely due to the Boudouard reaction, where we see spontaneous gasification happening when temperatures exceed 710 °C[2][3]. Although these observations were seen at temperatures lower than 710 °C it is most likely due to the catalytic capabilities of inorganics in TLW[1]. The researchers further investigated this by doing ICP-OES measurements and found that a fifth of the residual mass percentage was Ca species. CaCO3 is used in cigarette papers and filter material, which led the researchers to believe that the degradation of CaCO3 causes pure CO2 reacting with CaO in a dynamic equilibrium state[1]. This being the reason for seeing mass decay between 660 °C and 710 °C. The researchers also saw differences in differential thermogram (DTG) peaks for TLW compared to TSW. TLW had four distinctive peaks at 87, 195, 265, and 306 °C whereas TSW had two major drop offs at 200 and 306 °C with one spike in between[1]. The four peaks indicated that TLW contains more diverse types of additives than TSW[1]. The residual mass percentage between TLW and TSW was further compared, where the residual mass in TSW was less than that of TLW for both CO2 and N2 environments concluding that TSW has higher quantities of additives than TLW.

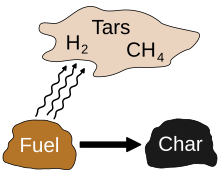

The one-stepwise pyrolysis experiment showed different results for the CO2 and N2 environments. During this process the researchers saw the evolution of 5 different notable gases. Hydrogen, Methane, Ethane, Carbon Dioxide, and Ethylene all are produced when the thermolytic rate of TLW began to be retarded at greater than or equal to 500 °C. Thermolytic rate begins at the same temperatures for both the CO2 and N2 environment but there is higher concentration of the production of Hydrogen, Ethane, Ethylene, and Methane in the N2 environment than that in the CO2 environment. The concentration of CO in the CO2 environment is significantly greater as temperatures increase past 600 °C and this is due to CO2 being liberated from CaCO3 in TLW[1]. This significant increase in CO concentration is why there is lower concentrations of other gases produced in the CO2 environment due to a dilution effect[1]. Since pyrolysis is the re-distribution of carbons in carbon substrates into three pyrogenic products[1]. The CO2 environment is going to be more effective because the CO2 reduction into CO allows for the oxidation of pyrolysates to form CO. In conclusion the CO2 environment allows a higher yield of gases than oil and biochar. When the same process is done for TSW the trends are almost identical therefore the same explanations can be applied to the pyrolysis of TSW[1].

Harmful chemicals were reduced in the CO2 environment due to CO formation causing tar to be reduced. One-stepwise pyrolysis was not that effective on activating CO2 on carbon rearrangement due to the high quantities of liquid pyrolysates (tar). Two-stepwise pyrolysis for the CO2 environment allowed for greater concentrations of gases due to the second heating zone. The second heating zone was at a consistent temperature of 650 °C isothermally[1]. More reactions between CO2 and gaseous pyrolysates with longer residence time meant that CO2 could further convert pyrolysates into CO[1]. The results showed that the two-stepwise pyrolysis was an effective way to decrease tar content and increase gas concentration by about 10 wt.% for both TLW (64.20 wt.%) and TSW (73.71%)[1].

References

- ^ a b c d e f g h i j k l m n o p q r s Lee, Taewoo; Jung, Sungyup; Lin, Kun-Yi Andrew; Tsang, Yiu Fai; Kwon, Eilhann E. (2021-01-05). "Mitigation of harmful chemical formation from pyrolysis of tobacco waste using CO2". Journal of Hazardous Materials. 401: 123416. doi:10.1016/j.jhazmat.2020.123416. ISSN 0304-3894.

- ^ Lahijani, Pooya; Zainal, Zainal Alimuddin; Mohammadi, Maedeh; Mohamed, Abdul Rahman (2015-01-01). "Conversion of the greenhouse gas CO2 to the fuel gas CO via the Boudouard reaction: A review". Renewable and Sustainable Energy Reviews. 41: 615–632. doi:10.1016/j.rser.2014.08.034. ISSN 1364-0321.

- ^ Hunt, Jacob; Ferrari, Anthony; Lita, Adrian; Crosswhite, Mark; Ashley, Bridgett; Stiegman, A. E. (2013-12-27). "Microwave-Specific Enhancement of the Carbon–Carbon Dioxide (Boudouard) Reaction". The Journal of Physical Chemistry C. 117 (51): 26871–26880. doi:10.1021/jp4076965. ISSN 1932-7447.