User:Mkoronowski/turbomachinery

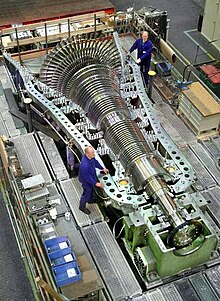

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid. The two types of machines are governed by the same basic relationships including Newton's second Law of Motion and Euler's energy equation for compressible fluids. This is illustrated by the horizontal axis of of both Figure_0.2 and 0.3. Centrifugal pumps are also turbomachines that transfer energy from a rotor to a fluid, usually a liquid, while turbines and compressors usually work with a gas.[1]

In actuality, there are two overall kinds of turbomachines are encountered in practice. Those that are open and those that are closed turbomachines. Open machines such as propellers, windmills, and unshrouded fans act as isolated airfoils within an infinite (boundary condition) extent of fluid. Conversely, closed machines operate more similarly as an infinite number of airfoils within a finite (boundary condition) quantity of fluid as it passes through a housing or casing (control volume).

As a result open turbo-machines have historically been designed and analyzed using wing theory. However, recent advances in CFD has shrunk the gap in applied mathematics such that unducted fans, as used on prototype aircraft engines, are closely related to their closed counterparts.

Historical Contributions, The Pioneers[edit]

The above explanation may seem trivial, but it is actually quite complex. Over this past 100 years, applied scientists like Stodola (1903, 1927-1945[2]), Pfleiderer (1952[3]), Hawthorne (1964[4]), Shepard (1956[5]), Lakshminarayana (1996[6]) and Japikse (numerous texts including, 1997[7]) have tried to educate young engineers in the fundamentals of turbomachinery which apply to all dynamic, continuous-flow, axisymmetric pumps, fans, blowers, and compressors in axial, mixed-flow and radial/centrifugal configurations.

This relationship is why advances in turbines and axial compressors frequently find their way into other turbomachinery including centrifugal compressors. Figures 1.1 and 1.2, illustrate the domain of turbomachinery with labels showing centrifugal compressors. Improvements in centrifugal compressors has not been achieved through large discoveries. Rather, improvements have been achieved through understanding and applying incremental pieces of knowledge discovered by many individuals.

Figure_1.1 represents the aero-thermo domain of turbomachinery. The horizontal axis represents the energy equation derivable from The First Law of Thermodynamics. The verticle axis, which can be characterized by Mach Number, represents the range of fluid compressibility (or elasticity). The Zed axis, which can be characterized by Reynolds Number, represents the range of fluid viscosities (or stickiness). Mathematicians and Physicists that established the foundations of this aero-thermo domain include: Sir Isaac Newton, Daniel Bernoulli, Leonard Euler, Claude-Louis Navier, Sir George Gabriel Stokes, Ernst Mach, Nikolay Yegorovich Zhukovsky, Martin Wilhelm Kutta, Ludwig Prandtl, Theodore von Karman, Paul Richard Heinrich Blasius, and Henri Coandă.

Figure_1.2 represents the physical or mechanical domain of turbomachinery. Again, the horizontal axis represents the energy equation with turbines generating power to the left and compressors absorbing power to the right. Within the physical domain the vertical axis differentiates between high speeds and low speeds depending upon the turbomachinery application. The Zed axis differentiates between axial-flow geometry and radial-flow geometry within the physical domain of turbomachinery. It is implied that mixed-flow turbomachinery lie between axial and radial. Key contributors of technical achievements that pushed the practical application of turbomachinery forward include: Denis Papin[8] , Kernelien Le Demour, Daniel Gabriel Fahrenheit, John Smeaton, Dr. A. C. E. Rateau[9] , John Barber, Alexander Sablukov, Sir Charles Algernon Parsons, Ægidius Elling, Sanford Moss, Willis Carrier, Adolf Busemann, Hermann Schlichting, and Frank Whittle.

Partial Time-Line[edit]

<1689 Early Turbomachines Pumps, blowers, fans 1689 Denis Papin Origin of the centrifugal compressor 1754 Leonhard Euler Euler's "Pump & Turbine" equation 1791 John Barber First gas turbine patent 1899 Dr. A. C. E. Rateau First practical centrifugal compressor 1927 Aurel Boleslav Stodola Formalized "slip factor" 1928 Adolf Busemann Derived "slip factor" 1937 Frank Whittle First gas turbine using centrifugal compressor >1970 Modern Turbomachines 3D-CFD, rocket turbo-pumps, heart assist pumps, turbocharged fuel cells

Turbomachines may be further classified into two additional categories: those that absorb energy to increase the fluid pressure, i.e. pumps, fans, and compressors, and those that produce energy such as turbines by expanding flow to lower pressures. Of particular interest are applications which contain pumps, fans, compressors and turbines. These components are essential in almost all mechanical equipment systems, such as power and refrigeration cycles.[10]

Dimensional analysis[edit]

To weigh the advantages between centrifugal compressors it is important to compare 8 parameters classic to turbomachinery. Specifically, pressure rise (p), flow (Q), speed (N), power (P), density (ρ), diameter (D), viscosity (mu) and elasticity (e). This creates a practical problem when trying to experimentally determine the effect of any single parameter. This is because it is nearly impossible to change one of these parameters independently.

The method of procedure known as Buckingham's Pi-Therom can help solve this problem by generating 5 dimensionless forms of these parameters.[5][7][11] These Pi parameters provide the foundation for "similitude" and the "affinity-laws" in turbomachinery. They provide for the creation of additional relationships (being dimensionless) found valuable in the characterization of performance.

For the examples below Head will be substituted for pressure and sonic velocity will be substituted for elasticity.

Π theorem[edit]

The three independent dimensions used in this procedure for turbomachinery are:

- Mass (Force is an alternative)

- Length

- Time

According to the theorem each of the eight primary parameters are equated to its independent dimensions as follows:

Flow: ex. = m^3/s Head: ex. = kg*m/s^2 Speed: ex. = m/s Power: ex. = kg*m^2/s^3 Density: ex. = kg/m^3 Viscosity: ex. = kg/(m*s) Diameter: ex. = m Speed of sound: ex. = m/s

Classic turbomachinery similitude[edit]

Completing the task of following the formal procedure results in generating this classic set of five dimensionless parameters for turbomachinery. Full similitude is achieved when each of the 5 Pi-parameters are equivalent. This of course would mean the to turbo-machines being compared are geometrically similar and running at the same operating point.

Flow coefficient: Head coefficient: Speed coefficient: Power coefficient: Reynolds coefficient:

Turbomachinery analysts gain tremendous insight into performance by comparisons of these 5 parameters with efficiencies and loss coefficients which are also dimensionless. In general application, the flow coefficient and head coefficient are considered of primary importance. Generally, for centrifugal compressors, the velocity coefficient is of secondary importance while the Reynolds coefficient is of tertiary importance. In contrast, as expected for pumps, the Reynolds number becomes of secondary importance and the velocity coefficient almost irrelevant.

Other dimensionless combinations[edit]

Demonstrated in the table below is another value of dimensional analysis. Any number of new dimensionless parameters can be calculated through exponents and multiplication. For example, a variation of the first parameter shown below is popularly used in aircraft engine system analysis. The third parameter is a simplified dimensional variation of the first and second. This third definition is applicable with strict limitations. The fourth parameter, specific speed, is very well known and useful in that it removes diameter. The fifth parameter, specific diameter, is a less frequently discussed dimensionless parameter found useful by Balje[12] .

Corrected mass flow coefficient: Alternate#1 equivalent Mach form: Alternate#2 simplified dimensional form: Specific speed coefficient: Specific diameter coefficient:

Affinity laws[edit]

The following "affinity laws" are derived from the five Pi-parameters shown above. They provide a simple basis for scaling turbomachinery from one application to the next.

From flow coefficient: From head coefficient: From power coefficient: From flow coefficient: From head coefficient: From power coefficient:

Turbomachinery[edit]

There are numerous types of dynamic continuous flow turbomachinery that can be referenced within Wikipedia. Below is a partial list of these entries. What is notable about this collection is that the fundamentals that apply to centrifugal compressors also apply to each of these entries. Certainly there are significant differences between these machines and between the types of analysis that are typically applied to specific cases. This does not negate the fact that they are unified by the same underlying physics of fluid dynamics, gas dynamics, aerodynamics, hydrodynamics, and thermodynamics.

|

See also[edit]

See also[edit]

- Secondary flow in turbomachinery

- Exoskeletal engine - an inside-out turbine

- Turbocharger

Sources[edit]

- Sydney Lawrence Dixon, Fluid mechanics and thermodynamics of turbomachinery, 1998

- Earl Logan (1993). Turbomachinery: basic theory and applications. CRC Press. ISBN 9780824791384.

- Erian A. Baskharone (2006). Principles of turbomachinery in air-breathing engines. Cambridge University Press. ISBN 9780521858106.

References[edit]

- ^ Logan, p.1

- ^ Aurel Stodola (1945). Steam and Gas Turbines. New York: P. Smith. OL 18625767M.

- ^ Pfleiderer, C. (1952). Turbomachines. New York: Springer-Verlag.

- ^

W. R. Hawthorne (1964). Aerodynamics Of Turbines and Compressors. Princeton New Jersey: Princeton University Press. ISBN LCCN 58-5029.

{{cite book}}: Check|isbn=value: invalid character (help) - ^ a b Shepard,Dennis G. (1956). Principles of Turbomachinery. McMillan. ISBN 0 - 471 - 85546 - 4. LCCN 56002849.

- ^ Lakshminarayana, B. (1996). Fluid Dynamics and Heat Transfer of Turbomachinery. New York: John Wiley & Sons Inc. ISBN 0-471-85546-4.

- ^ a b

Japikse, David & Baines, Nicholas C. (1997). Introduction to Turbomachinery. Oxford: Oxford University press. ISBN 0-933283-10-5.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Engeda, Abraham (1999). "From the Crystal Palace to the pump room". Mechanical Engineering. ASME.

- ^ Elliott Company. "Past, Present, Future, 1910-2010" (PDF). Elliott. Retrieved 1 May 2011.

- ^ Baskharone, p.6

- ^ Streeter, Victor L. (1971). Fluid Mechanics fifth edition. New York: McGraw Hill Book Company. ISBN 07-062191-8.

{{cite book}}: Check|isbn=value: length (help) - ^ Balje, O. E. (1961). Turbo Machines; a Guide to Design, Selection, and Theory. New York: John Wiley & Sons. ISBN 0-471-06036-4.

This article needs additional citations for verification. (November 2009) |