User:Prof McCarthy/mechanicaladvantage

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. Ideally, the device preserves the input power and simply trades off forces against movement to obtain a desired amplification in the output force. The model for this is the law of the lever. Machine components designed to manage forces and movement in this way are called mechanisms.

An ideal mechanism transmits power without adding to or subtracting from it. This means the ideal mechanism does not include a power source, and is frictionless and constructed from rigid bodies that do not deflect or wear. The performance of real systems is obtained from this ideal by using efficiency factors that take into account friction, deformation and wear.

Law of the lever

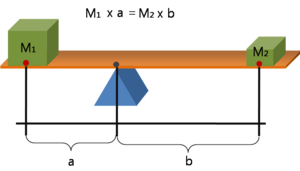

[edit]The lever is a movable bar that pivots on a fulcrum attached to the ground. The lever operates by applying forces at different distances from the fulcrum, or pivot.

As the lever rotates around the fulcrum points farther from this pivot move faster than points closer to the pivot. The power into and out of the lever must be the same, so forces applied to points farther from the pivot must be less than when applied to points closer in.[1]

If a and b are distances from the fulcrum to points A and B and let the force FA applied to A is the input and the force FB applied at B is the output, the ratio of the velocities of points A and B is given by a/b, so we have the ratio of the output force to the input force, or mechanical advantage, is given by

This is the law of the lever, which was proven by Archimedes using geometric reasoning.[2] It shows that if the distance a from the fulcrum to where the input force is applied (point A) is greater than the distance b from fulcrum to where the output force is applied (point B), then the lever amplifies the input force. If the distance from the fulcrum to the input force is less than from the fulcrum to the output force, then the lever reduces the input force.

The use of velocity in the static analysis of a lever is an application of the principle of virtual work.

Speed ratio

[edit]The requirement for power input to an ideal mechanism to equal power output provides a simple way to compute mechanical advantage from the input-output speed ratio of the system.

Power input to a gear train with an input torque TA applied to the drive pulley which rotates at an angular velocity of ωA. This defines the power input to the gear train as P=TAωA.

The torque TB and angular velocity ωB of the output gear must satisfy the relation

which yields

This shows that for an ideal mechanism the input-output speed ratio equals the mechanical advantage of the system. This applies to all mechanical systems ranging from robots to linkages.

Gear trains

[edit]Gear teeth are designed so that the number of teeth on a gear is proportional to the radius of its pitch circle, and so that the ptich circles of meshing gears roll on each other without slipping. The speed ratio for a pair of meshing gears can be computed from ratio of the radii of the pitch circles and the ratio of the number of teeth on each gear..

The velocity v of the point of contact on the pitch circles is the same on both gears, and is given by

where input gear A has radius rA and meshes with output gear B of radius rB, therefore,

where NA is the number of teeth on the input gear and NB is the number of teeth on the output gear.

The mechanical advantage of a pair of meshing gears for which the input gear has NA teeth and the output gear has NB teeth is given by

This shows that if the output gear GB has more teeth than the input gear GA, then the gear train amplifies the input torque. And, if the output gear has fewer teeth than the input gear, then the gear train reduces the input torque.

If the output gear of a gear train rotates more slowly than the input gear, then the gear train is called a speed reducer. In this case, the output gear will have more teeth than the input gear, which means a speed reducer amplifies the input torque.

Chain and belt drives

[edit]Mechanisms consisting of two sprockets connected by a chain, or two pulleys connected by a belt are designed to provide a specific mechanical advantage in a power transmission systems.

The velocity v of the chain or belt is the same when in contact with the two sprockets or pulleys:

where the input sprocket or pulley A meshes with the chain or belt along the pitch radius rA and the output sprocket or pulley B meshes with this chain or belt along the pitch radius rB,

therefore

where NA is the number of teeth on the input sprocket and NB is the number of teeth on the output sprocket. For a timing belt drive, the number of teeth on the sprocket can be used. For friction belt drives the pitch radius of the input and output pulleys must be used.

The mechanical advantage of a pair of a chain drive or timing belt drive with an input sprocket with NA teeth and the output sprocket has NB teeth is given by

The mechanical advantage for friction belt drives is given by

Chains and belts dissipate power through friction, stretch and wear, which means the power output is actually less than the power input, which means the mechanical advantage of the real system will be less than that calculated for an ideal mechanism. A chain or belt drive can lose as much as 5% of the power through the system in friction heat, deformation and wear, in which case the efficiency of the drive is 95%.

Example bicycle chain drive

[edit]Consider the 18-speed bicycle with 7in cranks and 26in wheels. If the sprockets at the crank and at the rear drive wheel are the same size, then the ratio of the output force on the tire to the input force on the pedal can be calculated from the law of the lever to be

Now, consider the small and large front sprockets which have 28 and 52 teeth respectively, and consider the small and large rear sprockets which have 16 and 32 teeth each. Using these numbers we can compute the following speed ratios between the front and rear sprockets

| input (small) | input (large) | output (small) | output (large) | speed ratio | crank-wheel ratio | total MA | |

|---|---|---|---|---|---|---|---|

| low speed | 28 | - | - | 32 | 1.14 | 0.54 | 0.62 |

| mid 1 | - | 52 | - | 32 | 0.62 | 0.54 | 0.33 |

| mid 2 | 28 | - | 16 | - | 0.57 | 0.54 | 0.31 |

| high speed | - | 52 | 16 | - | 0.30 | 0.54 | 0.16 |

The ratio of the force driving the bicycle to the force on the pedal, which is the total mechanical advantage of the bicycle, is the product of the speed ratio and the crank-wheel lever ratio.

Notice that in every case the force on the pedals is greater than the force driving the bicycle forward. This keeps the pedal crank speed low relative to the speed of the drive wheel even at low overall speeds.

Block and tackle

[edit]Tackle is the assembly of a rope and pulleys that is used to lift apply forces. The pulley assembly is called a block. A block and tackle is a rope and pulley system designed to provide mechanical advantage.

In order to determine the mechanical advantage of a block and tackle system consider the simple case of a gun tackle, which has a single mounted pulley and a single movable pulley. The rope is threaded around the mounted block and falls down to the moving block where it is threaded around the pulley and brought back up to be knotted to the mounted block.

Let S be the distance from the axle of the mounted block to the end of the rope', which is A where the input force is applied. Let R be the distance from the axle of the mounted block to the axle of the moving block, which is B where the load is applied.

The total length of the rope L can written as

where K is the constant length of rope that passes over the pulleys and does not change as the block and tackle moves.

The velocities VA nd VB of the points A and B are related by the constant length of the rope, that is

or

The negative sign shows that the velocity of the load is opposite to the velocity of the applied force, which means as we pull down on the rope and the load moves up.

Let VA be positive downwards and VB be positive upwards, so this relationship can be written as the speed ratio

where 2 is the number of ropes connecting the mounted block to the moving block.

Let FA be the input force applied at A the end of the rope, and let FB be the force at B on the moving block. Like the velocities FA is directed downwards and FB is directed upwards.

For an ideal block and tackle system there is no friction in the pulleys and no deflection or wear in the rope, which means the power input by the applied force FAVA must equal the power out acting on the load FBVB, that is

The ratio of the output force to the input force is the mechanical advantage of an ideal gun tackle system,

This analysis generalizes to an ideal block and tackle with a moving block supported by n ropes,

This shows that the force exerted by an ideal block and tackle is n times the input force, where n is the number of sections of rope that support the moving block.